AI-powered Optimization

Optimize for Profit in High-Mix, Low-Volume Environments

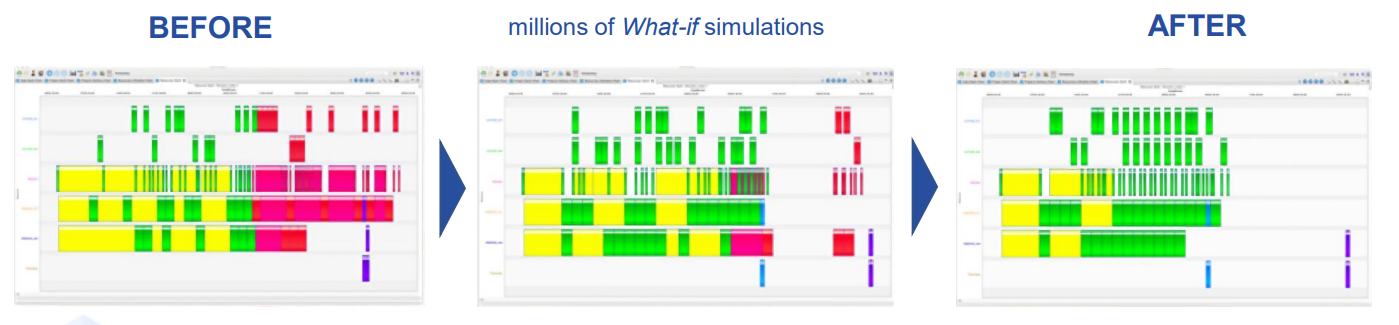

Harness prescriptive AI to optimize up to 5 KPIs simultaneously from over 50 built-in options, balancing throughput, costs, and time. Move beyond basic rules-based scheduling to unlock more capacity with intelligent adjustments. Automatically evaluate trade-offs between competing KPIs, prioritizing production based on profitability, costs, revenue, and sustainability. Optional automatic MRP runs and incremental lot sizing further minimize waste, while continuous machine-learning auto-tuning ensures ongoing efficiency improvements.

MangoGem’s scheduling algorithms are key to our capacity advantage. Chasing throughput on a bottleneck line makes no sense – it's about maximizing value per minute. If anyone reverts to manual scheduling, they'll be out. AI-driven automation is non-negotiable for us.

Pieter Vanderhaeghen, COO of Fin-Col Group

We’ve seen many solution providers but this is the 1st time that someone reverts to us with a relevant answer that can model our reality. The demonstrated +70% productivity is more than what we were expecting in our most optimistic scenario.

Laurent Geron, CTO IONICS